Various High-Quality Products for Laser Cutting, Magnification, Temperature Monitoring, Cordless Cleaning, and Enhanced Reading

Various High-Quality Products for Laser Cutting, Magnification, Temperature Monitoring, Cordless Cleaning, and Enhanced Reading

1) Laser Cutting:

When it comes to laser cutting, precision and accuracy are key. High-quality laser cutting machines are designed to deliver superior cutting performance. These machines utilize advanced technology and are equipped with powerful laser sources to ensure clean and precise cuts. They offer a wide range of customizable options, allowing users to cut various materials such as metals, plastics, wood, and more. With user-friendly interfaces and automated features, these machines make the laser cutting process efficient and less time-consuming.

2) Magnification:

In industries such as electronics, medical, and research, microscopic details matter. High-quality magnification devices such as digital microscopes are essential for capturing these fine details. These devices provide exceptional magnification capabilities, allowing users to view objects in incredible detail. They are equipped with high-resolution cameras and advanced imaging software, enabling users to visualize and analyze the smallest of features. Additionally, these devices often feature adjustable lighting, precise focusing mechanisms, and ergonomic designs to enhance user experience.

3) Temperature Monitoring:

In industries where temperature control is crucial, high-quality temperature monitoring systems play a vital role. These systems utilize advanced sensors and probes to accurately monitor and control temperature conditions. They often come with integrated data logging capabilities, allowing users to gather data and analyze temperature trends over time. These systems are widely used in sectors such as pharmaceuticals, food processing, and environmental monitoring to ensure compliance with safety standards and prevent thermal damage to sensitive materials.

4) Cordless Cleaning:

Traditional cleaning methods can be time-consuming and inefficient. High-quality cordless cleaning tools such as cordless vacuum cleaners and pressure washers offer a convenient and effective solution. These tools are powered by advanced battery technology, providing strong suction power or high-pressure water flow without the limitations of cords. With ergonomic designs and versatile attachments, these cordless cleaning tools make cleaning tasks easier and more efficient.

5) Enhanced Reading:

For individuals with visual impairments or those who simply enjoy reading, high-quality reading aids can significantly enhance the reading experience. These aids include electronic magnifiers that can enlarge text, adjust contrast, and even read aloud through text-to-speech technology. Other reading aids may include e-readers with adjustable font sizes and background colors, as well as audiobook devices for those who prefer listening to written material. These products give individuals with reading difficulties the opportunity to access and enjoy written content more comfortably.

In conclusion, high-quality products in laser cutting, magnification, temperature monitoring, cordless cleaning, and enhanced reading contribute to improved efficiency, accuracy, and convenience in various industries and everyday life. These products are the result of continuous innovation and technological advancements, providing users with the tools they need to excel in their respective fields and enhance their overall quality of life.

|

3pcs Laser machine Mo Si Copper Mirror Lenses Diameter 19.05/20/25/30/38.1mm Thickness 3mm for CO2 Cutting Engraving Engraver |

| Check Price |

|

30X Illuminated Large Magnifier Handheld 12 LED Lighted Magnifying Glass for Seniors Reading Jewelry Watch Reading Loupe |

| Check Price |

|

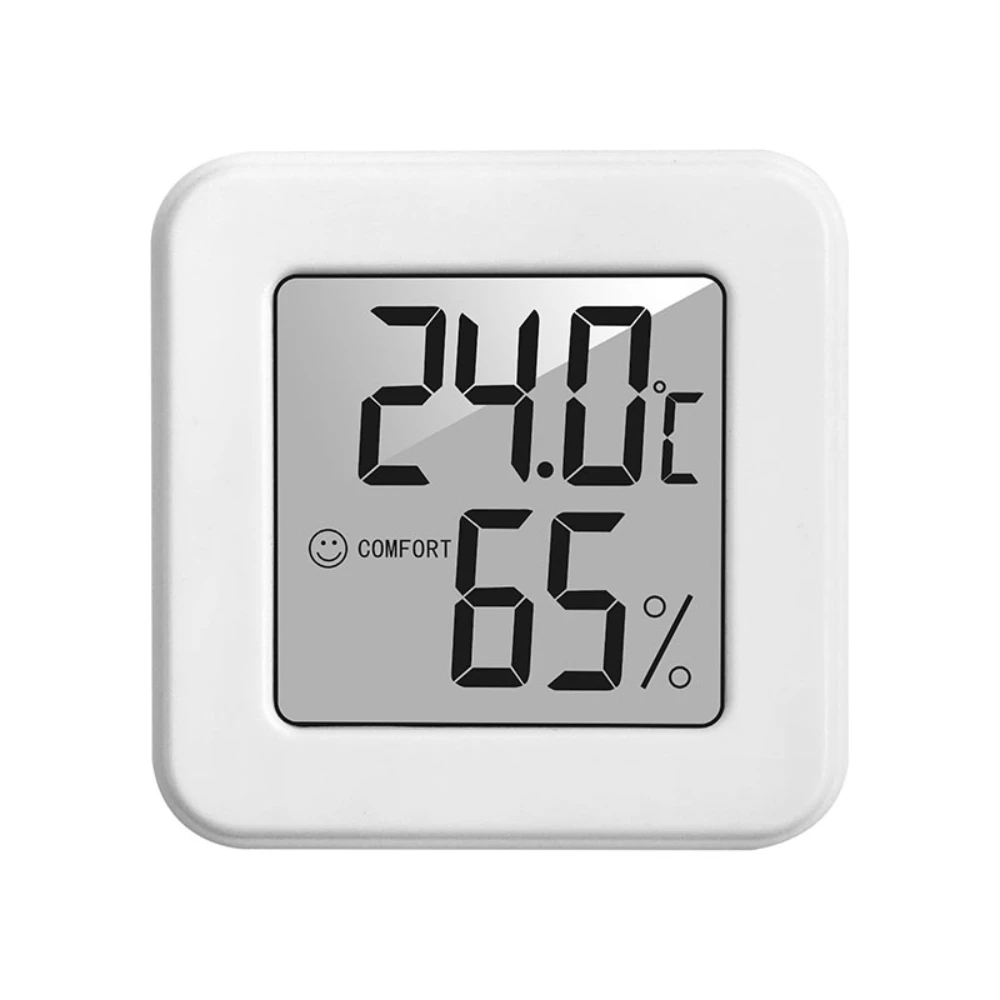

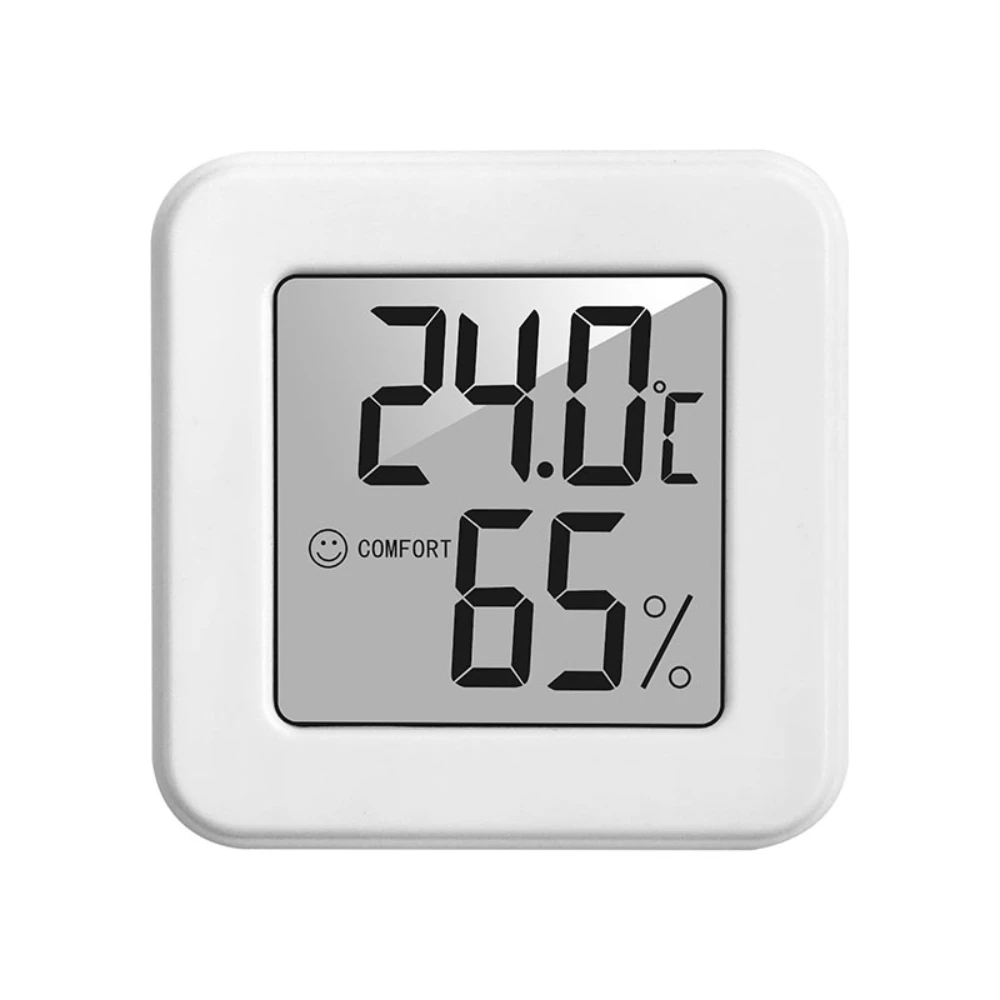

Mini Indoor Thermometer LCD Digital Temperature Room Hygrometer Gauge Sensor Humidity Meter Indoor Air Conditioner Thermometer |

| Check Price |

|

2-in-1 Jobsite Cordless Blower & Vacuum,21V Max Lightweight Handheld Small Dry Leaf Sawdust Blower Cleaner |

| Check Price |

|

10X Headband Glasses Magnifier Adjustable Size LED Magnifier Loupe Glasses For Reading Optivisor Magnifier Illuminated |

| Check Price |

3pcs Laser machine Mo Si Copper Mirror Lenses Diameter 19.05/20/25/30/38.1mm Thickness 3mm for CO2 Cutting Engraving Engraver

Introduction

Laser technology has revolutionized various industries, including manufacturing, engraving, and cutting. One essential component of a laser machine is the Mo Si Copper Mirror Lenses. These lenses play a crucial role in focusing the laser beam and ensuring precise and accurate engraving and cutting. In this article, we will explore the features and benefits of 3pcs Laser machine Mo Si Copper Mirror Lenses with different diameters and thicknesses for CO2 cutting and engraving engravers.

The Significance of Mo Si Copper Mirror Lenses

Mo Si Copper Mirror Lenses are specifically designed for CO2 laser machines and are widely used in various applications, such as engraving, cutting, and marking. These lenses are highly efficient and provide exceptional beam quality and focus. Let’s delve into the key features and benefits of these lenses.

Features of Mo Si Copper Mirror Lenses

1. Diameter Options:

The Mo Si Copper Mirror Lenses are available in different diameters, including 19.05mm, 20mm, 25mm, 30mm, and 38.1mm. This wide range of options allows users to select the lens suitable for their specific laser machine requirements.

2. Thickness:

These lenses have a thickness of 3mm, ensuring durability and stability during the engraving and cutting process. The thickness also contributes to the overall performance and longevity of the lens.

3. Material Composition:

The lenses are made of Mo Si Copper, a material known for its excellent thermal conductivity and stability. This material choice ensures efficient heat dissipation, which is crucial to prevent lens damage and maintain optimal performance.

4. High Reflectivity:

The Mo Si Copper Mirror Lenses exhibit high reflectivity, enabling efficient beam redirection and focusing. The high reflectivity ensures minimal energy loss, resulting in precise engraving and cutting outcomes.

Benefits of Using Mo Si Copper Mirror Lenses

1. Enhanced Beam Quality:

The lenses’ high reflectivity and composition contribute to improved beam quality, resulting in sharper and more accurate engraving and cutting. This ensures that intricate designs and fine details can be achieved with ease.

2. Increased Efficiency:

Utilizing Mo Si Copper Mirror Lenses in CO2 laser machines significantly enhances the overall efficiency of the engraving and cutting processes. The lenses’ high reflectivity allows for optimal energy utilization, reducing wastage and improving productivity.

3. Longevity and Durability:

Thanks to their robust construction and high-quality materials, these lenses offer exceptional durability. Their resistance to thermal stresses and corrosion ensures a prolonged lifespan, reducing the need for frequent replacements and maintenance.

4. Versatility:

The Mo Si Copper Mirror Lenses are highly versatile and compatible with a wide range of CO2 laser machines. Whether you are involved in wood engraving, acrylic cutting, or metal marking, these lenses can cater to your diverse needs.

Applications of Mo Si Copper Mirror Lenses

1. CO2 Laser Engraving:

The Mo Si Copper Mirror Lenses excel in CO2 laser engraving applications. Whether it is engraving intricate designs on wood, personalizing items, or etching patterns on glass, these lenses provide exceptional precision and depth.

2. CO2 Laser Cutting:

When it comes to CO2 laser cutting, the Mo Si Copper Mirror Lenses are the go-to choice due to their high reflectivity and beam quality. These lenses enable clean and accurate cuts on various materials, including acrylic, leather, fabric, and more.

3. CO2 Laser Marking:

In the field of industrial marking, Mo Si Copper Mirror Lenses play a vital role. They ensure legible and durable markings on metals, plastics, and other materials. The high reflectivity ensures excellent contrast and readability.

SEO Optimization

To optimize the SEO for this article, we will incorporate relevant keywords that align with the topic. These keywords include “Mo Si Copper Mirror Lenses,” “CO2 Cutting Engraving Engraver,” “laser machine,” and “diameter 19.05/20/25/30/38.1mm thickness 3mm.” By including these keywords naturally throughout the article, it becomes more likely to rank higher in search engine results, allowing readers seeking information on these topics to find this article easily.

Conclusion

In conclusion, the 3pcs Laser machine Mo Si Copper Mirror Lenses with diameters of 19.05/20/25/30/38.1mm and a thickness of 3mm are indispensable components for CO2 laser cutting and engraving. The features and benefits offered by these lenses make them essential for achieving precise, efficient, and high-quality results in various applications. Whether you are involved in engraving, cutting, or marking, incorporating these lenses in your laser machine setup will undoubtedly elevate your performance and productivity. [4]

30X Illuminated Large Magnifier Handheld 12 LED Lighted Magnifying Glass for Seniors Reading Jewelry Watch Reading Loupe

Mini Indoor Thermometer LCD Digital Temperature Room Hygrometer Gauge Sensor Humidity Meter Indoor Air Conditioner Thermometer

2-in-1 Jobsite Cordless Blower & Vacuum,21V Max Lightweight Handheld Small Dry Leaf Sawdust Blower Cleaner

10X Headband Glasses Magnifier Adjustable Size LED Magnifier Loupe Glasses For Reading Optivisor Magnifier Illuminated

The contents of this text are not directly related to the product.